Dyson electric car cancelled? Design, battery, and motor details

Dyson was planning to apply the engineering expertise, which had made them a household name with their unique vacuum cleaners, to the electric car world. However, they recently announced they will be cancelling their premium electric car project. As of a few weeks ago they were actively working on the project, aiming to produce an innovative design that leveraged cutting edge technologies developed in-house. What made them change their mind when it came to taking on Tesla and Nissan?

Dyson electric car design elements

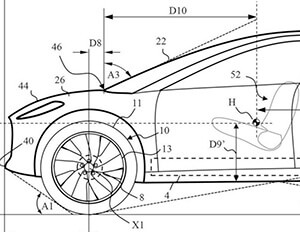

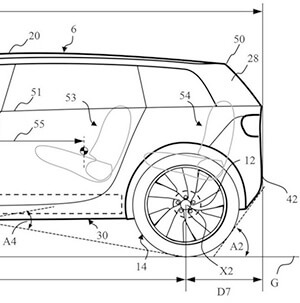

The automotive press was anticipating a crossover-type vehicle with an elongated and svelte design from Dyson in 2021. This hype was based on three patents the company had released back in the spring of 2019, which revealed some of the design philosophy guiding the all-British automotive team.

What was clear at that early stage, was that the car would have unique low-profile tires on larger-than-usual wheel diameters. Additionally, the wheelbase was going to be fairly wide when compared to the total length of the car. Had Dyson gone into production, this would have meant that the body overhang at either end would have been greatly minimised.

While the aesthetic details were changing as the design was being refined, the hypothetical mockup provided by Autocar UK clearly established a fundamental reimagining of the large family car

Dyson’s now-cancelled approach can be distilled down to its three interconnected benefits:

- Low weight and smooth aerodynamic profile

- High-performance battery with mileage range enhanced by car shape and custom tires

- Driver and passenger comfort facilitated by enhanced interior design

Based on these published patents, industry observers predicted that the production car would have been five metres long. Dyson was also said to be focussing on the front profile to make it as small as possible in order to maximise performance for the car overall.

Thanks to the thin battery design, the car could actually both ride higher and have a lower roof without sacrificing interior space. It was expected to accommodate up to seven people while the driver maintained a commanding driving position.

Who was the target market?

While there were no specific details on pricing or market segment, it was fairly telling that James Dyson had mentioned both Range Rover and Tesla when talking about the now-cancelled project. This implied that Dyson was vying for market share at the top end of the automotive market where those brands dominate.

Dyson was looking to sell the car worldwide and, rather unusually, China was at the top of the list of launch countries. This may not be that surprising considering that China has one of the largest automotive markets in the world with fantastic growth.

Dyson surrounded himself with an executive team composed of some of the brightest stars in the luxury car sector. For starters, Roland Krueger was poached from Nissan’s luxury marque “Infiniti.” He was set to helm the construction of a state-of-the-art production facility in Singapore, which will now be either cancelled or repurposed.

Other notable leaders who joined the Dyson camp were Ian Minards, who led the engineering division at Aston Martin, and Ian Robertson, a BMW board member . These personnel choices gave credence to the rumours of a price point in the low six figures.

Battery, powertrain and electric motor features

Dyson’s patent diagrams showed that the battery would have conformed to the wheelbase of the chassis, supporting the vehicle body. This would have been possible thanks to Dyson’s work on solid-state technology which would have superseded current lithium-ion battery designs. The extra height of the initial design would have made additional features possible, such as variable-height profile suspension.

The company did validate rumours that they were investigating the feasibility of two distinct solid-state battery designs. This meant that Dyson was seeking to leapfrog current market leaders such as Tesla and BMW and their lithium ion-based technologies.

The patent documents were light on details when it came to battery and powertrain specifications. However, the platform concept that was envisioned, afforded a wider latitude when it came to power options. The car could have come with several engine flavours:

- Full EV drivetrain

- Petrol-EV hybrid

- Hydrogen drivetrain

It was also very likely that the final automotive design would have incorporated more than one motor, if the company had gone forward with the project. This would have been due to the possibility of exploiting the benefits of power regeneration during braking or downshifting phases during driving.

When the car was announced, the automotive press made a very big deal about Dyson’s long-standing expertise in developing their own electric motors. Therefore, the bespoke motor design was expected to be a prominent unique selling point, had the car gone to market. Specifically, the Dyson motor concept was supposed to bring increased efficiency and small size to stand out in the increasingly crowded EV market.

Proposed Singapore manufacturing plant

While the car was slated to be designed and engineered in Wiltshire, Dyson was going to set up a manufacturing base in Singapore. These plans are all now up in the air following the announcement of the project’s cancellation. The main rationale for not manufacturing in the UK was that Singapore is much closer to what chief executive Jim Rowan defined as “high-growth markets.” Additionally, unlike China, Singapore has a fairly solid track record when it comes to respecting patent and intellectual property.

The other benefits of a Singapore plant would have been more logistical in nature. Rowan wrote to staff that Singapore gave Dyson a point of entry to world class "supply chains, access to markets and the availability of the expertise that will help us achieve our ambitions," when the project was still moving forward.

Dyson was planning to invest £2.5bn to develop several new key technologies in-house. The lion’s share of that figure was lined up for the new manufacturing and assembly plant in Singapore. With the recent cancellation news, it’s unclear if the plant will actually happen or if there will instead be a redesign to support existing product lines.

Dyson electric automotive jobs

Before the recent news, Dyson was aggressively growing its automotive team. Their jobs page revealed how they were organising their efforts to make an electric car. These are the areas where they were seeking expertise up until the last minute.

1. Cooling & Climate Control

It looks like Dyson was planning to partner with Siemens for battery cooling and climate control assemblies. The company was looking for people who could check that the supplied parts would meet specifications and matched the bill of materials (BOM) requirements set forth by an envisioned Environmental Control team.

2. Feature and software design

Without a sizeable engine block under the bonnet, electric vehicles give car manufacturers a chance to redefine what a car is. Much less mechanical engineering is involved in EVs and this means that a lot of resources can be retasked to create new features not widely available on petrol-based vehicles.

At the same time, the new features and unique aspects of EVs introduce new concepts that have to be communicated clearly to drivers through clear user experience (UX) design. For example, battery capacity and regenerative braking are key EV concepts that are completely new to someone coming from a traditional petrol-based car.

Additionally, the emergence of autonomous functionality on some electric cars has to be clearly shown to the driver through new dashboard graphic elements, both for their convenience and safety. The cutting-edge work done by software teams across the automotive industry contributes directly to making these new experiences as positive as possible.

3. Electronics

Without having to control or design around a combustion engine, electric cars offer a lot of opportunities for car designers. For example, the low-slung and flat design of automotive electric batteries gives EVs superior handling characteristics and road grip when compared to combustion-based cars in the same class.

The absence of a combustion engine also presents some new challenges. Electric cars are much more dependent on electronic systems for optimal operation. This means that the electronics in an EV are much more pervasive and therefore have to be relied on much more heavily for mission-critical tasks that require 100% uptime.

Dyson was looking to put together their own electronics team. This demonstrated that they were serious about coming up with new and unique solutions to core EV functions, such as power management and drivetrain sensors. This work would have impacted how the car responded to driver input, as well as those emerging autonomous features we mentioned earlier.

4. Project management

The car design process is made up of many teams and many moving parts, especially when new technologies are concerned. In order to keep all the teams on task and moving towards a common goal, you need to have experienced people who have a good understanding of how challenges in one area can impact the project as a whole.

More importantly, they need to be able to bring people together to find solutions to issues as they emerge while keeping an eye on the big picture to ensure that the vision of the product is fulfilled as faithfully as possible while keeping to stringent deadlines and budgetary considerations.

5. Safety

Electric vehicles are just emerging from the early-adopter stage when it comes to market penetration and new technologies. While EVs such as Tesla score very highly in safety tests, they don’t have the same track record fuel-based cars have when it comes to safety. This means that while combustion-engine-based cars have a long history of flaws and oversights, manufacturers and safety standards bodies also have a much deeper understanding when it comes to durability, points of failure and potential safety enhancements.

Because electric cars are relatively new and don’t have the same operational record as their petrol-burning brethren, safety engineers are crucial to ensure all the complex systems in the interact safely.

6. Interior design

Passenger comfort is a primary concern for car manufacturers, and Dyson would have been no exception had they gone further forwards into the automotive world. Once more there are new differences and opportunities when comparing electric vehicles with petrol-powered cars. Interior design for petrol-powered cars focuses on mitigating noise and vibrations through sound insulation and comfortable seating.

Electric cars need much less space for drivetrain components, which results in a much more spacious cabin and an eerily quiet ride. Drivers who are used to the background noise of a combustion engine may find the serenity of driving an EV unsettling.

This may be due to the fact that driving over certain surfaces can cause certain sounds that would have been masked by a loud combustion engine. This means the interior design team would have been tasked with coming up with solutions to maintain a high standard of passenger comfort inside the car, no matter its drivetrain.

Why did Dyson abandon its electric vehicle aspirations?

James Dyson announced the cancellation of his electric car aspirations in a terse press release.

I wanted you to hear directly from me that the Dyson Board has therefore taken the very difficult decision to propose the closure of our automotive project.

Initial reports on the closure seem to point to insurmountable logistical and financial challenges to get the car into production. Even though the team had several functional prototypes being tested, there was no guarantee of moving forward to a production stage. An unnamed employee told The Independent that the car’s manual was not far off from being written, but it was all for nought.

The current consensus is that Dyson underestimated the expertise and investment required to bring the project to fruition. The company may have put too much faith in their own engineering brilliance to fully grasp the financial and logistical hurdles that plague the automotive market.

After all, many established car manufacturers with their decades of sunk costs and expertise are finding it hard to get on board the EV revolution. Even Tesla, the poster child of the EV industry, is constantly teetering on the edge of financial difficulty as it experiences growing pains at the supply-chain level.

At the end of the day, there is only so much British ingenuity can do. Dyson was pretty unique in trying to go it alone, instead of finding industry partners to develop a common platform. There is still hope, however, that some of the technologies Dyson developed will be licensed to other car makers in the future.

What do electric vehicles bring to the table?

Electric vehicles are a key component in making the UK energy transition a successful one. The primary benefit they bring is a significant reduction in carbon emissions and pollutants that reduce air quality and contribute to the global warming crisis.

Once electric vehicles are more widely adopted they will have a resounding impact on electricity distribution. One of the challenges the national grid faces when integrating renewable energy is how to balance out supply and demand. EVs may, quite unexpectedly, hold the key to solving this problem.

An electric vehicle can be thought of as essentially a battery on wheels. This means that they can be used as a source of electricity to even out peaks in supply and demand. While EVs are plugged in and charging, they are essentially connected to the grid. With intelligent software, the national grid could “talk” to car batteries and pull electricity from vehicle batteries that can “sell back” unused storage capacity.

With more sensors and electronics being packed into cars, it would be easy for each car to build a driving profile of its owner which could then let it autonomously trade electricity with the national grid while it’s not being driven around. Drivers or vehicle owners could be rewarded for participating in such a scheme by getting discounts on their electricity bill or through a government incentive like the Feed In tariff.

As fleets of electric commercial vehicles come online, this type of concept has a real chance of becoming a reality. The question is which energy companies will be prepared to harness this business opportunity.

Another area of automotive market where electric vehicles are going to upend things is the notion of car ownership, which has been the driving force of the British car market until now. Electric vehicles further enable the idea of vehicles as a service. While car and ride-sharing apps are testing what is possible in this domain, the real disruption to the car industry will come when autonomous driving technology becomes commonplace.

At that point, car-sharing services, which currently have only seen traction in urban areas, will allow customers to summon a vehicle to a location and either have the vehicle take them autonomously to their destination or let them drive with some computer assistance or guidance.

Think about it: Having a car come to you and take you where you need to go for a flat monthly subscription makes the prospect of purchasing and maintaining your own car much less appealing.